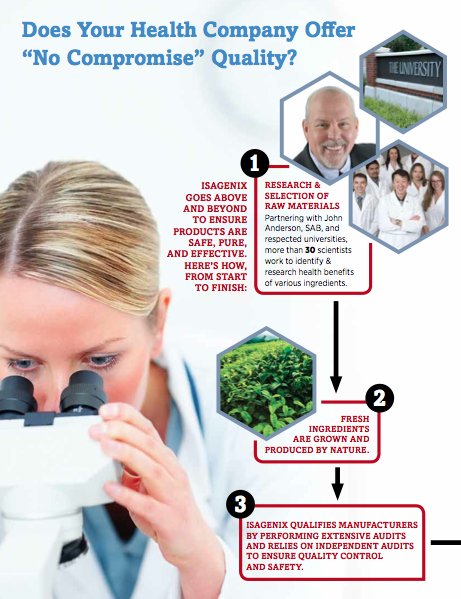

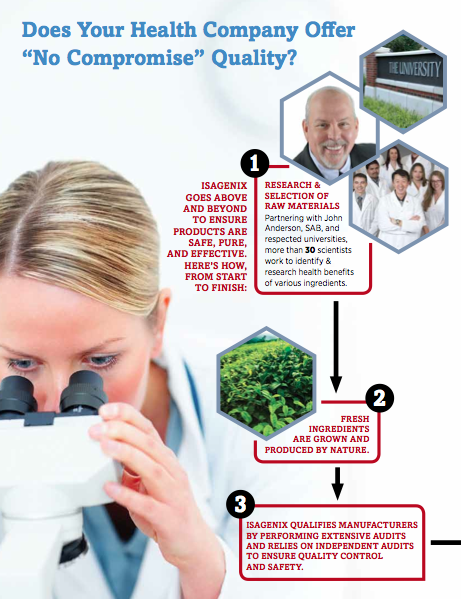

To view our “No Compromise” Quality Assurance visual, click the picture to the left or here.

As it should be, your safety is our first priority at Isagenix. Having safe, effective, “no compromise” products means giving no slack when it comes to selecting and testing raw materials, following the appropriate regulatory guidelines, and verifying that the finished products meet purity and composition standards.

The Isagenix “No Compromise” Quality Policy is extensive and thorough, covering every detail from ingredient sourcing to manufacturing guidelines. By following key procedures, Isagenix can stand by their products with confidence.

Research and selection of raw materials

After a product has been proposed and approved, it’s time to select the best source of the raw material to begin formulation. Quality ingredients could mean the difference between products having no effect and providing fantastic results. At Isagenix, raw materials are only sourced from suppliers with a proven track record of sustainability and quality.

One of the best examples of Isagenix’s quality standards is the whey protein found in IsaLean shakes. New Zealand undenatured whey protein was carefully selected after vigorous research and testing because the quality of the protein can’t be beat. It’s the best of the best.

Meet and exceed manufacturing guidelines

“No Compromise” quality does not stop after raw materials have been selected. When the ingredients are delivered to the manufacturing facility, there are strict guidelines with how materials are handled. These guidelines that define how manufacturing should be conducted are known as current Good Manufacturing Practices (cGMPs). Isagenix works to ensure that all products meet or exceed the highest standards of cGMPs for dietary supplements.

cGMPs are outlined by the FDA and other international regulatory boards such as Health Canada and the Therapeutic Goods Administration (TGA) in Australia. These guidelines include authenticity, quarantine and release procedures, potency and purity testing of raw materials and finished products, cleanliness of the facility, employee training, and documentation (1-3).

Meeting all of these guidelines can make the release of products internationally a fairly complicated, yet beneficial, process. Through this series of checks and balances, Isagenix can stand by the quality of its products with pride.

Standardized testing methods

Isagenix also adheres to detailed written Standard Operating Procedures (SOPs) to ensure consistency and safety in each phase of our manufacturing process. One SOP Isagenix follows requires that every raw material that arrives in the manufacturing facilities be immediately quarantined, thoroughly inspected, and tested for:

• Identity (botanicals & phytochemicals)

• Strength & composition

• Organoleptic properties (taste, color, odor, & texture)

Any raw materials that do not meet these standardized testing methods are rejected or destroyed. Additionally, the testing that is done to confirm safety and purity of raw materials is very extensive. Rigorous testing is performed for:

• Microbial activity: total aerobic bacterial, yeast and mold, salmonella and E. coli strains, and other bacterial strains

• Pesticides, herbicides, and fungicides

• Heavy metals: all botanicals are tested for the presence of lead, mercury, cadmium, and arsenic

• PCBs and dioxins: each batch of fish oil is third-party tested for heavy metals, PCBs, and dioxins

Finished product verification

In addition to testing raw materials, Isagenix is unique in that they also thoroughly evaluate the efficacy of finished products. This includes re-analyzing the product for identity and purity. Third-party claim testing on vitamin and mineral content is also conducted to ensure the products fully meet what is said on their labels. Finally, stability testing is done to confirm that the strength and composition as indicated on the label of the product is accurate up until at least the expiration date.

Statistical process control

Another major role of Isagenix Quality Assurance is statistical process control. This involves tracking trends to ensure product quality is continuously monitored and upheld. By putting this much care and attention towards product quality and safety, Isagenix knows it’s doing right by its customer and their health.

References

1. Food & Drug Regulations. U.S. Food and Drug Administration. Retrieved July 2013, from www.fda.gov

2. National Archives and Records Administration. (2007). Code of Federal Regulations: Food and Drugs. Washington, D.C: author.

3. Tortora et al. Microbiology: An Introduction. 11th Edition, 2012.